It’s always 420 somewhere, right? Well at Solstrip.com it’s 420 all April long, with 10% savings across the board on all SolStrip products. Just use the code 10APRIL at checkout to secure your discount. Happy shopping!

It’s always 420 somewhere, right? Well at Solstrip.com it’s 420 all April long, with 10% savings across the board on all SolStrip products. Just use the code 10APRIL at checkout to secure your discount. Happy shopping!

I developed SolStrips and SolSheet lamps and lamp kits in 2017 because I wanted to offer boutique and personal gardeners an alternative to poorly made, underperforming “blurple” LED grow lights and costly high-end commercial systems costing thousands of dollars. Like you, I was tired of being treated like an idiot by LED manufacturers selling their lights like snake oil salesmen, playing fast and loose with their performance claims, and refusing to offer their customers credible component specifications so that they could make informed decisions about their lighting needs.

So I began studying the technology behind LED lighting. What I found was that the technology was changing at light speed (pun intended). And blurple light makers had missed it, or chosen to ignore it, in order to sell their overpriced colored-diode lights. Blurple wasn’t the state-of-the-art at all, in terms of being the best technology for delivering a high-intensity field of plant-usable photons over a given area.

What I discovered was that virtually all the innovation in spectrum, intensity, efficiency and durability was in so-called white LEDs. Some of the largest research and development efforts in the lighting industry were being directed at creating white LEDs that not only were ultra-efficient, but could create specific spectral environments in virtually every combination in the visible spectrum. And they were doing so at twice or 3x the efficiency, and less than one-third the cost of quality mono color LEDs.

This new highly tunable and efficient LED lighting technology was first introduced as “chip-on-board” or COB, lights. COBs placed dozens of these new white diodes close together to create intense, high wattage light emitters capable of replicating the intensity of HID lamps, but at nearly twice the efficiency. Using parts purchased from electronics distributors, I built a several COB systems and tested them in a number of environments. They quickly proved their value, delivering high-quality light at the intensity that met or exceeded HID lighting, with less waste heat and much higher efficiencies.

COBs sold me on the promise of LED lighting for gardeners, especially those with smaller spaces. Not only were heat issues greatly decreased compared to HID lighting, but COB technology allowed for a much thinner vertical profile for these lights, often just a few inches. This gave small space growers precious vertical space to grow their plants, rather than waste it on reflectors, ventilation ducting, fans, air conditioners and hangers.

But most importantly, COBs allowed small space growers to move away from single-source high-intensity discharge lamps, which either needed light movers (more expense and lost vertical space) or needed to be hung high enough to light the entire canopy well yet low enough to deliver the intensity needed to produce quality yields. With COBs, hotspots under the lamp and light-deficient areas at the canopy perimeter could be reduced, and a more evenly intensive light field created. In fact, the COB systems I built that used several lower-wattage COBs seemed to produce better quality and yields than systems with just a few large high-wattage COBs.

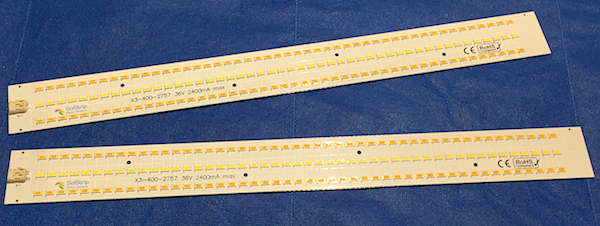

This was the epiphany that led me to the SolStrip concept: distributed diode LED technology was the future of indoor garden lighting.

The concept of distributed diode lighting is deceptively simple, yet it is lost on most lighting manufacturers. It is based on the fundamental understanding that, under natural sunlight conditions, outdoor plants receive light from multiple points and angles across the sky, constantly due to refraction of the sun’s rays through the atmosphere, and daily due to the Earth’s rotation from sunrise to sunset.

Outdoor plants are bombarded by sunlight from hundreds of angles throughout the day, and develop their structures and leaves to take advantage of this barrage of photonic energy. Yet grow light manufacturers have largely pursued the idea of creating single-point lighting systems, promoting the idea that the best solution to light a larger space is a single, larger wattage lamp. This focus on ever higher wattage single-emitter lamps has benefitted light manufacturers seeking to sell the “next year’s model” of light as ever more powerful with ever more impressive output metrics, but it flies in the face of the basic tenets of physics and botany, which states that the strongest light is the closest light, and that plants thrive best when they receive light energy from all angles rather than a single point directly above them.

SolStrips distribute the sources of light (the LEDs) across the entire plant canopy, creating that multi-point light field that plants need to develop flowers and fruits at their most productive potential. And the waste heat that is inevitably produced by electric lighting is distributed as well, where is can be managed better, allowing the lights to be positioned much closer to the plant canopy. That increases exponentially the intensity of the light reaching the canopy, so that growers can finally achieve the goal of providing sun-like light across their garden spaces, evenly and without burning.